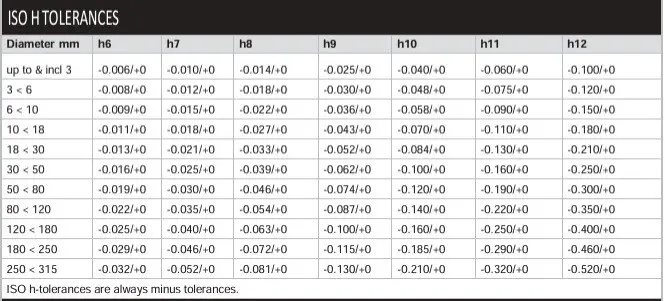

The peeling (skin removal) process aims to eliminate surface defects of bars without any change to their mechanical properties. An automatic peeling machine entirely carries out this process in the production line of POOLAD SIM. In this process, bars produced by the hot rolling method are first transferred to the straightening line to straight bar and then moved to the peeling line. Rotating head equipped with knives of carbide blades ensures the removal of surface layer with common metallurgical defects. As a result of peeling one

obtains a product with flawless surface and with high accuracy of diameter – class IT9. After the process is complete, the bars are sent to a chamfering machine for edge beveling, and then to a two-roll straightening machine for final polishing and straightening.

Automotive industry

Machine building industries

Production of precision tools and equipment

Production of fittings, screws, nuts and…

Electrotechnical industries

Production of hydraulic equipment, pneumatic cylinders, etc.

Agricultural equipment and machinery

Rail industries

Mining equipment and supplies

Production of household appliances

| Weight | 100kg |

|---|---|

| Length | 2m |

Unit 2, 6th Floor, No.53, Mahya Building, Opposite Youssefian St, Motahari Street, Tehran, Iran.

POOLAD SIM FACTORY, 3RD ST, RESSALAT BLVD, PHASE 3, MAHMOUD ABAD INDUSTRIAL PARK QOM PROVINCE, IRAN

All rights to the site and design belong to POOLADSIM.